In the fast-paced automotive industry, precision, speed, and reliability are essential in manufacturing processes. One of the most critical operations in vehicle production is welding—ensuring structural integrity, safety, and consistent quality across every chassis and component. For OEMs, tier-one suppliers, and automation integrators, selecting the right automotive welder is crucial to meet high-volume production targets while maintaining flexibility for innovative designs.

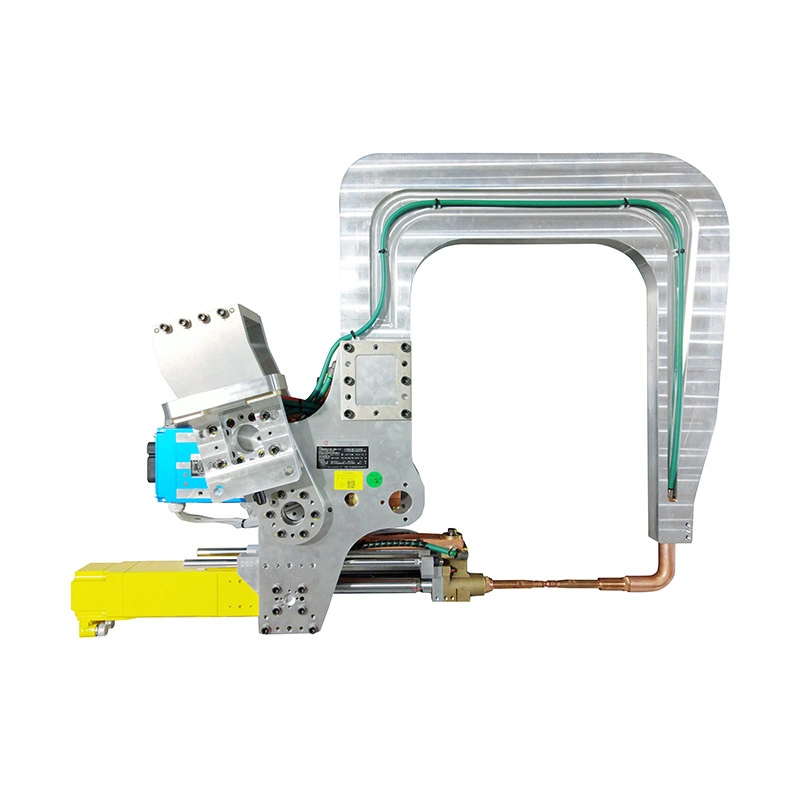

Heron Welder, a global leader in industrial welding solutions, offers a complete range of resistance welding machines, self-pierce riveting systems, clinching tools, and automated production lines designed to elevate automotive manufacturing efficiency.

Understanding Automotive Welders

An automotive welder is a specialized machine used to join metal components in vehicle production. These welders are engineered to handle high-volume, repetitive tasks while ensuring consistent quality. Modern automotive welders include:

-

Spot Welding Machines: Ideal for joining sheet metals in car bodies, doors, and panels.

-

Projection Welding Systems: Used for joining components with preformed projections, often found in complex assemblies.

-

Seam Welding Machines: Provides continuous welds for fuel tanks, pipes, and leak-proof components.

-

MFDC & Capacitor Discharge Welders: Offer precision welding for thin or heat-sensitive metals, reducing distortion.

Each system is designed to meet specific manufacturing requirements while ensuring minimal downtime and optimized energy consumption.

Principles of Automotive Welding

Automotive welding relies on controlled heat and pressure to join metal components. The most common method in vehicle assembly is resistance welding, where electrical current passes through the metal to create localized heat at the contact point. Key principles include:

-

Electrical Resistance: The metal’s resistance to current generates heat.

-

Pressure Application: Electrodes apply force to ensure a solid metallurgical bond.

-

Time Control: Precise timing ensures consistent weld strength without damaging materials.

Advanced automotive welders from Heron integrate intelligent controllers, monitoring weld quality in real time and adapting parameters to variations in material thickness or type.

Applications in Automotive Manufacturing

Automotive welders are essential for various applications across vehicle production lines:

-

Chassis Assembly: Spot welding ensures structural rigidity in frames and body-in-white construction.

-

Door Panels and Hoods: Seam and projection welding deliver precise, durable joints.

-

Battery Packs & Electric Vehicles: MFDC and capacitor discharge welders allow joining of thin sheets and copper-aluminum connections with minimal heat distortion.

-

Interior and Exterior Components: Clinching and self-pierce riveting systems provide metal joining without welding fumes or paint damage.

By deploying the right welding solution, manufacturers can achieve faster cycle times, consistent quality, and lower maintenance costs.

Comparing Automotive Welding Technologies

Selecting the optimal automotive welder depends on production requirements, material types, and design complexity. Here’s a quick comparison:

| Welding Type | Best For | Advantages | Limitations |

|---|---|---|---|

| Spot Welding | Body panels, chassis | High speed, reliable joint | Limited to lap joints |

| Projection Welding | Complex assemblies, brackets | Accurate, minimal surface damage | Requires projections |

| Seam Welding | Fuel tanks, pipes | Continuous welds, leak-proof | Slower for small components |

| MFDC / Capacitor Discharge | Thin sheets, battery tabs | Minimal distortion, precise | Higher equipment cost |

| Clinching / FSPR | Non-weldable metals, coated surfaces | No heat, paint-friendly | Limited joint strength |

Heron Welder provides flexible solutions across all these technologies, enabling manufacturers to choose systems tailored to their specific production needs.

Best Practices for Automotive Welding

Maximizing performance and longevity of automotive welders requires attention to key operational practices:

-

Proper Electrode Maintenance: Regularly dress and align electrodes to prevent inconsistent welds.

-

Material Preparation: Clean and properly stack sheets to reduce weld defects.

-

Parameter Optimization: Set current, pressure, and timing based on material type and thickness.

-

Integrated Quality Monitoring: Use real-time sensors and controllers to track weld strength and avoid rework.

-

Automation Integration: Combine welding machines with robotic arms and conveyors for consistent, high-volume production.

Adopting these practices ensures higher productivity, reduced downtime, and improved weld quality, aligning with the demands of modern automotive manufacturing.

Why Choose Heron Automotive Welding Solutions?

Heron Welder is a trusted partner for global OEMs and automation integrators, delivering:

-

Comprehensive Product Range: From spot and projection welders to automated production lines and FSPR systems.

-

Advanced Control Systems: Intelligent, user-friendly interfaces with real-time quality monitoring.

-

Customization: Tailored solutions for unique production challenges, including EV battery welding and lightweight materials.

-

Global Support & Expertise: Experienced engineers providing installation, training, and maintenance services worldwide.

By leveraging Heron’s expertise, manufacturers can streamline operations, reduce waste, and increase overall production efficiency.

FAQs About Automotive Welders

1. What materials can automotive welders handle?

Heron welders can join a variety of metals including steel, stainless steel, aluminum, and coated sheets commonly used in automotive manufacturing.

2. Are these welders compatible with automation systems?

Yes, Heron provides fully automated solutions integrating robots, conveyors, and controllers for high-volume production lines.

3. How do I choose the right welding technology for my application?

It depends on material type, joint design, production volume, and quality requirements. Heron engineers can provide a detailed assessment to select the optimal solution.

4. What maintenance is required for automotive welders?

Routine electrode dressing, cleaning, and parameter calibration are recommended to maintain consistent weld quality and extend equipment life.

5. Can Heron welders support EV manufacturing?

Absolutely. MFDC, capacitor discharge, and FSPR systems are ideal for joining battery packs, thin sheets, and lightweight materials used in electric vehicles.

Conclusion: Transform Your Automotive Production

Selecting the right automotive welder is a critical step for manufacturers aiming to achieve precision, efficiency, and reliability in vehicle production. Heron Welder’s global expertise, advanced technologies, and customizable solutions make it the ideal partner for OEMs, automation integrators, and factory decision-makers seeking to enhance production processes.

Ready to optimize your automotive welding operations? Contact Heron Welder today to request a quote or consult with our engineers for a customized welding and automation solution tailored to your manufacturing needs.